Properties of Polyurethane Foam

Polyurethane foam insulation is preferred by homeowners for several reasons: Its heat-resistant characteristic is acknowledged by global users, especially those living in cold regions. Polyurethane foam is formed by the chemical reaction between isocyanate prepolymer and polyol; a blowing agent (carbon dioxide) and catalyst (amine) are also used in the process.

This material is applied on roofs, attics, foundations, basements, cellars, overlappings between floors, inner sections, and storerooms. In addition, it can be used on structural elements of arcades, doors, balconies, pipes, and more. Vessels, such as yachts, boats, and trailers can also be insulated.

Properties of Polyurethane Foam

Polyurethane foam is manufactured in two categories:

- Closed-cell rigid polyurethane foam

- Open-cell flexible polyurethane foam

Insulation

Polyurethane foam is an excellent insulator for thermal and acoustic purposes. It offers a high R-value (thermal resistance), making it beneficial for buildings, refrigeration, and HVAC systems. Polyurethane foam insulation is 700% better than bricks and 50% superior than glass wool.

Lightweight

Polyurethane foam is lightweight, easy to handle, and transportable. The lightweight attribute is beneficial for the sustainability of different industries, including waterproofing: It reduces the emission of greenhouse gases, use of resources, and waste sent to landfills.

Read More

Benefits of Assessing Cost for Roof Heat Proofing in Karachi

How Can You Save Money Through Heat Proofing in Pakistan?

Equipment Used for Roof Heat Proofing in Karachi

Cushioning and Comfort

Polyurethane foam is renowned for its cushioning and comfort properties. It provides a soft and supportive feel, making it suitable for use in mattresses, furniture, upholstery, and seating applications. PU foams absorb energy at a controlled and consistent rate: They are used to reduce static stress on shock-attenuation material or affect resonance.

Resilience

Polyurethane foam offers excellent tensile strength, i.e., it can easily return to its original shape upon compression. It is used in materials, such as shoe soles, sports equipment, and packaging. PU foam can modify shock pulse frequencies and render efficiency.

Versatility

Polyurethane foam can be manufactured in different forms, densities, and firmness levels. Moreover, it can be produced as flexible foam, rigid foam, or as a combination of both, depending on the specific requirements of the application. PU foam is self-extinguishing and easily molded to exact specifications.

Durable

Polyurethane foam is durable and long-lasting. It can withstand a range of environmental conditions, including temperature variations, moisture, and chemical exposure, without significant degradation. It maintains low conductivity due to its structure; it offers a useful life of 40 years or more.

Excellent Adhesion

PU foam has outstanding adhesion properties because of its cross-link polymer network. This feature allows it to bond well with various substrates, such as metals, plastics, and wood. It is widely used in the construction and manufacturing industry. However, it should be protected from UV light by plaster or paint, or by the use of a sealing agent.

Flame Resistant

Depending on the specific formulation and additives, polyurethane foam can exhibit flame retardant properties. This property is useful for fire-prone places, such as furniture, automotive interiors, and insulation for buildings.

With a fire rating of Class 1, spray-on polyurethane foam insulation is one of the most feasible solutions for structural heat proofing. 15% of components in the solution are fire-retardant.

Read More

Is There any Low-Cost Solution Than Roof Heat Proofing Service in Pakistan?

What are the Properties of Insulation Foam Spray in Pakistan?

How to Calculate Spray Foam Insulation Price in Pakistan?

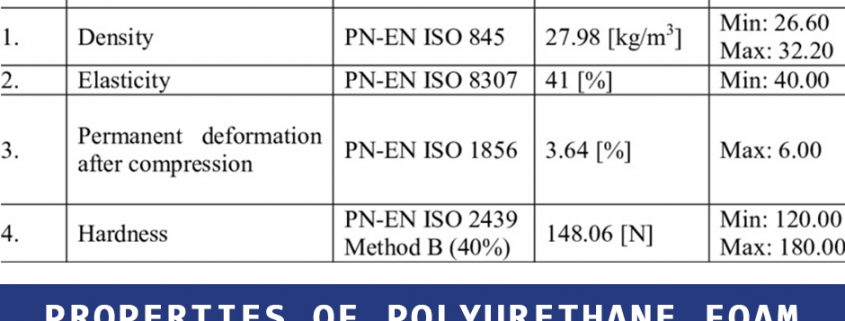

Characteristics of Polyurethane Foam

Like other chemicals, polyurethane also functions on specific limitations:

- Density: 0.5-1.5 lb/ft3 (Low) & 2 lb/ft3 and more (High)

- Thermal conductivity: 0.022 – 0.035 W/m.K

- Permissible airflow: 2.0 ft3/min

- Resilience: 20% ball rebound to 80% rebound

- R/inch: 3.6 – 6.7

- Diffusivity: 0.023 x 10e-6

It’s worth noting that the exact properties of polyurethane foam can vary depending on the specific formulation, manufacturing process, and additives used. If you want to know more about polyurethane foam or want to have it applied in your premises, contact Lakhwa Chemical Services.

Leave a Reply

Want to join the discussion?Feel free to contribute!