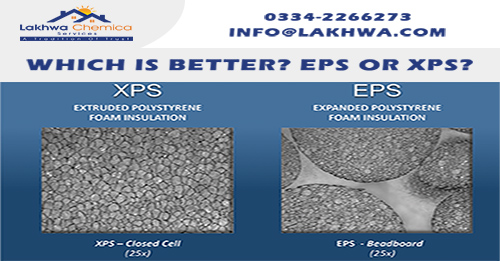

Which is Better? EPS OR XPS?

EPS and XPS are popular types of foam insulation materials used in the construction industry. EPS (Expanded Polystyrene) is a lightweight, rigid foam with excellent thermal insulation properties. XPS (Extruded Polystyrene) offers superior moisture resistance and higher compressive strength. Both materials provide effective insulation, reducing energy consumption and enhancing building comfort.

In this article, we’ll examine the qualities of EPS and XPS in detail.

EPS

This insulating material is made from beads of expanded polystyrene. Due to its outstanding insulating qualities, EPS is a popular choice for applications, including packaging, building construction, and even craft projects.

Benefits

Affordability is one of its main benefits. Because EPS is less expensive than its counterpart, it is preferred for insulation projects. EPS is also resistant to moisture absorption, which makes it the best choice for below-grade applications and damp environments.

Read More

Is LAC Heat Reflector Applied to Buildings?

Is Roof Cooling Paint in Karachi Secured for the Elderly?

Is Heat Reflective Roof Paint in Karachi the Only Solution for Heat Wave?

Drawbacks

There are some restrictions on EPS. Compared to XPS, it has a lower compressive strength, which makes it less appropriate for applications involving heavy loads. Additionally, exposure to some chemicals and solvents can harm the layer. Therefore, it is crucial to comprehend the project before selecting EPS as the insulating material.

XPS

XPS, also called, Extruded Polystyrene (XPS), is a blue or pink board, produced by the extrusion process. The insulation qualities of XPS are comparable to those of EPS. However, it differs greatly.

Benefits

The compressive strength of XPS is one of its key benefits. Due to their increased rigidity and durability, XPS insulation boards are suited for situations where significant loads are anticipated, such as underneath concrete slabs or roofing constructions. XPS is recommended for applications where moisture control is essential since it has a closed-cell structure that offers superior resistance to moisture absorption.

Drawbacks

XPS is manufactured using non-renewable fossil fuels, which raises environmental concerns. Secondly, it is not biodegradable and can persist in the environment for extended periods. Lastly, XPS emits greenhouse gases. In other words, it offers a larger GWP (Global Warming Potential) than EPS.

Read More

Why is Roof Heat Proofing Chemical Marketed at Low Cost in Pakistan?

Does Heat Resistant Paint Work in Garages?

List of Benefits Using Roof Cool Services in Karachi?

EPS & XPS – The Best Choice for Insulation Boards

Although the similarities and differences are prevalent, EPS and XPS are, nonetheless, important for heat insulation purposes. Your project’s needs and budget will determine their selection.

EPS is a fantastic option for homeowners and businessmen because of its properties: It is more resistant to moisture absorption than XPS. In addition, its compressive strength is lower. On the other hand, XPS is a better choice for areas where moisture control is necessary. However, it is necessary to consider the manufacturing time and higher costs.

Key Differences

| Parameters | EPS | XPS |

| Water Vapor Diffusion Resistance | 30-70 | 80-250 |

| Compressive Strength | Higher | Lower |

| Moisture Resistant | Lower | Higher |

| Environmental Friendly | More | Less |

Determining whether EPS (Expanded Polystyrene) or XPS (Extruded Polystyrene) is better depends on various factors. For example, XPS is more suitable for applications that require greater load-bearing capacity. Moreover, it is flame-retardant. Likewise, EPS offers multiple benefits too. Evaluate your needs and priorities before making a decision.

Conclusion

Consider the requirements of your project, such as load-bearing requirements, moisture exposure, budget, and environmental impact, carefully before making a choice. Expert advice or professional consultation might also yield insightful information. It’s necessary to consider local building laws and regulations in your area in addition to the previously listed elements.

It’s also important to remember that EPS and XPS are recyclable materials. Both insulation kinds can be recycled at several locations. You can choose your preference according to different factors. Or, better to hire a reliable firm like Lakhwa Chemical Services and relish the experience.

Leave a Reply

Want to join the discussion?Feel free to contribute!